Premier Pressure Control manufactures the Torus line is a division of Piper. We have been the sole manufacturer of the Torus line since 1985 when we acquired the molds and rights from Hughes Offshore.

Download Our Torus Brochure Here

The unique design of the Torus Annular BOP makes it perfectly suited for use with projects involving electric submersible pumps. An important concern on these work-overs is protection of the electric wire conduit while retaining the ability to effectively and quickly control well kicks. The Torus Annular BOP is designed to “cradle” single or multiple down hole objects with instant response time.

Please visit PremierPressureControl.com for greater details!

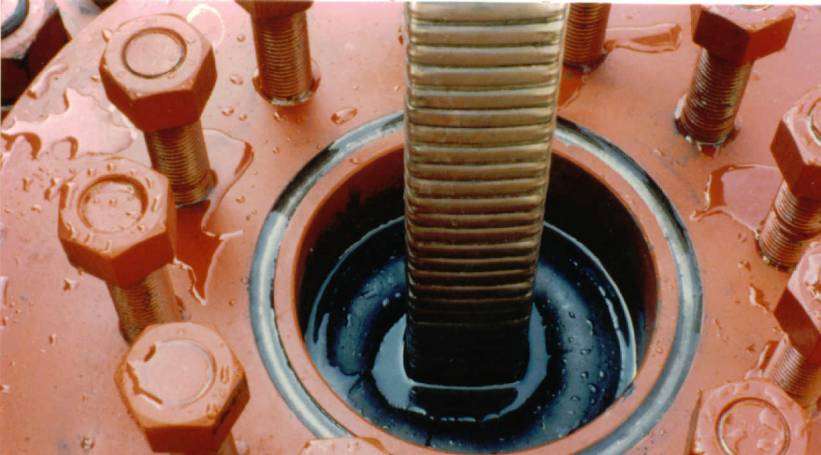

The Torus Annular Blowout Preventer is a unique design in well control technology. Unlike other annulars, the Torus employs no metal fingers in its packing element. This allows the BOP to close around multiple objects in the well bore as well as over open hole, without damage to delicate equipment such as electric submersible pump cable or fiberglass tubing. In addition, the Torus has no moving mechanical parts such as pistons and dynamic seals that are easily damaged by foreign material in the closing fluid. The outer packer acts as a diaphragm to transfer the hydraulic pressure to the inner packer and close the BOP.

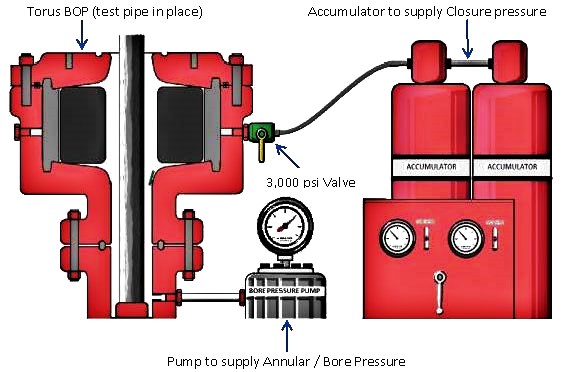

Unlike other annular blowout preventers on the market, the Torus is a pressure-close/vent-open BOP, and can be operated with any pressured media including nitrogen, water, or hydraulic fluid. Hydraulic fluid is preferred. One high pressure flexible hose, preferably 1” hose, is necessary to connect the pressure source to only one of the two 1” NPT ports located on the Torus body. Two (2) 1” ports are available on the Torus, 180 degrees apart, for convenience only. On an accumulator closing unit that employs a 4-way, 3-position shear seal valve (typical hardware), the hydraulic hose should be connected to the “Close” port on the back of the closing unit. The “Open” port must be plugged. A 1” 3,000 psi ball valve is recommended to be installed between the Torus and the hydraulic hose (discussed in detail below).

Another feature of the Torus is that it employs a 1:1 closing ratio. That is, if the wellbore pressure is 1,000 psi for example, the hydraulic closing pressure necessary to shut off the wellbore pressure is 1,000 psi plus 100 psi (+/-). This is a desirable feature for stripping operations because the “fine-tuning” capability reduces the frictional force between the object(s) being stripped and the inner packing element of the Torus. If stripping operations are to be an ongoing operation, a special hydraulic pressure regulator should be installed on the hydraulic closing unit that will more readily permit these infinite pressure control—manual hydraulic regulators do not provide such precise control.